Thermal Transfer (TT) Labels are the premium choice for applications demanding maximum durability, longevity, and resistance to harsh industrial environments. Unlike Direct Thermal (DT) labels, which use heat to chemically change the label surface (causing fading over time), TT labels utilize a ribbon that melts ink onto the label surface. This method creates an image that is physically bonded to the label material, making it highly resistant to sunlight (UV exposure), temperature extremes, chemicals, abrasion, and moisture. For applications that require extended readability—such as asset tagging, long-term warehouse storage, or compliance labeling—Thermal Transfer is the superior, reliable choice.

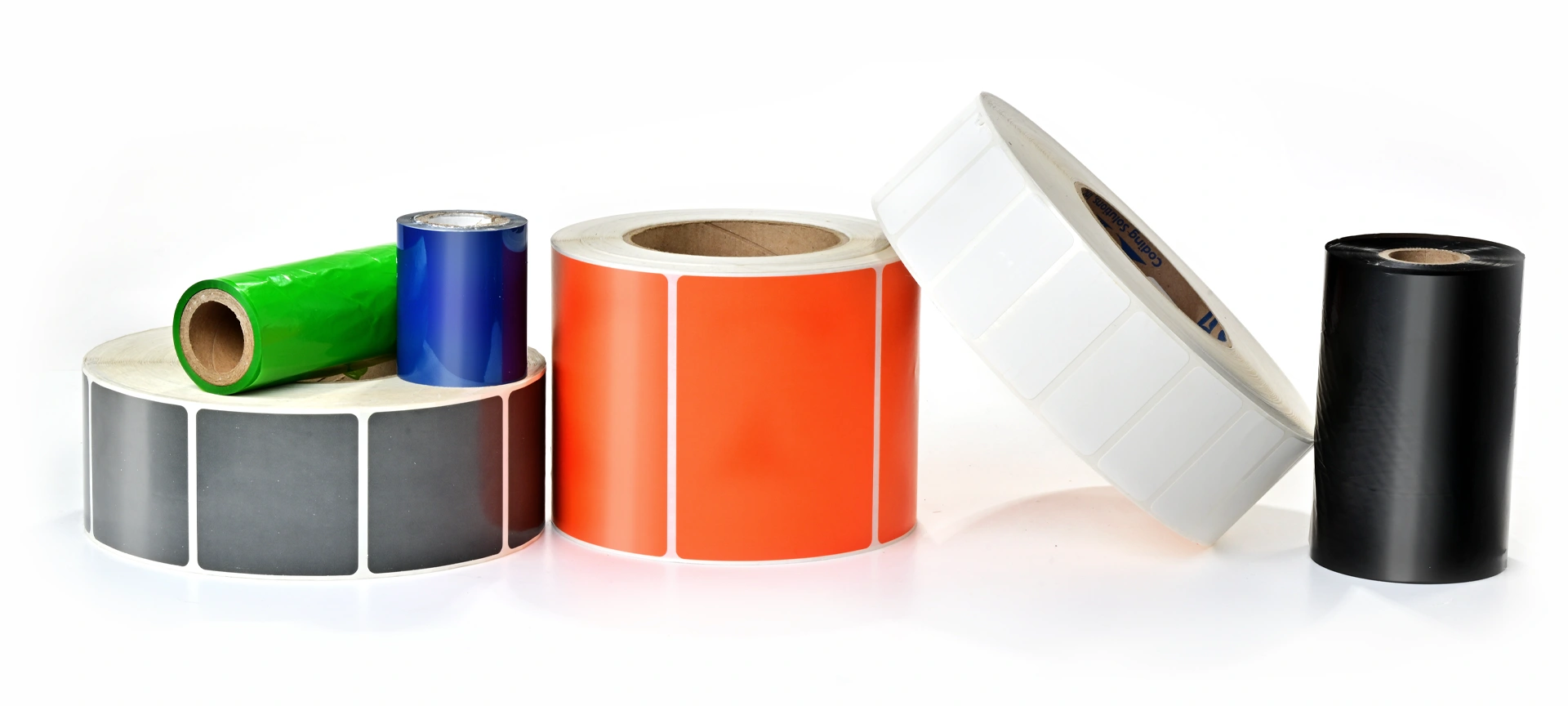

When you are operating in complex supply chains, TT labels provide an essential layer of security and compliance. Our TT solutions guarantee that your variable data, barcodes, and serial numbers remain 100% scannable and legible for years, not months. This durability eliminates the costly risk of unscannable labels failing quality control inspections or leading to inventory loss due to fading. The versatility of TT printing allows you to choose from various ribbon and label material combinations—including wax, resin, or hybrid—to match your exact environmental needs, from printing on simple paper for short-term internal use to using synthetic (poly-based) materials for extreme chemical exposure and outdoor longevity.

Choosing Thermal Transfer labels from Coding Solutions is an investment in your operational efficiency and long-term compliance. While the initial cost may be slightly higher than Direct Thermal due to the ribbon requirement, the Total Cost of Ownership (TCO) is lower for long-life products because you virtually eliminate label failure and relabeling costs. We partner with you to select the precise ribbon-media combination that secures your data, protects your brand, and ensures regulatory adherence for the lifetime of your product.

Images created using a thermal ribbon are cured onto the label, preventing fading and ensuring the label remains legible and scannable for years, not months.

Provides market-leading resistance to harsh conditions, including UV light, moisture, extreme cold, heat, and abrasion.

When paired with a resin or wax/resin ribbon, the printed image resists smearing from oils, cleaning agents, and solvents.

Compatible with a vast range of label stocks, including rugged synthetics (polypropylene, vinyl, polyester) ideal for asset tagging and chemical drum labeling.

Ideal for applications requiring permanent identification and traceability, such as GHS, serialization, and mandated lifetime product labeling.

Produces crisp, ultra-sharp edges on text and barcodes, ensuring excellent density and reliable 100% first-pass scanning on all regulatory symbologies.

Eliminates the need for costly relabeling and prevents fines associated with non-compliant or failed identification in the supply chain.

CSI provides certified media solutions for all major industrial printer brands.